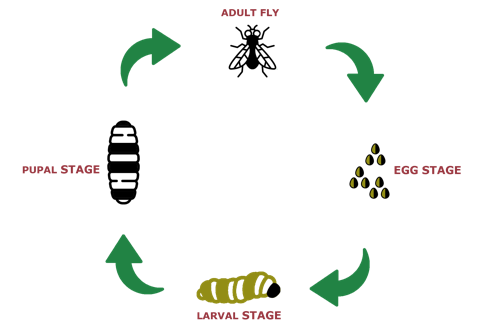

Substrate

Substrate is larvae feed

In this link organic residual flows are mixed and upscaled to certified substrate. Today the residual flows consist of vegetable and fruit waste, but in the future kitchen waste (Swill) and waste form supermarkets (FFS) can also be used. Sadly, one third of our produced food ends up as waste. RavenFeed, in collaboration with partners, uses this waste as a raw material instead of fermenting, composting or even incinerating it.

Contact